What is Ground Flat Stock?

Ground Flat Stock (GFS) is alloyed steel manufactured into flat strips and precision ground to insure that four sides are bright, clean, and free of surface defects and carburization. It may be referred to as gage stock, shim stock, key stock, plates, sheets, strips, squares, or flats. The grinding process is normally done with a surface grinder to insure a smooth surface finish and tightly controlled dimensional tolerances.

- Nominal Sizes

- Price vs. Performance

- Delivery Time and Inventory Quantity

- Steel Grades, Sizes, and Manufacturers

- Regular Tolerance vs Oversize Tolerance vs Cold-Drawn

- Manufacturer Tolerances

- Steel Grades and Processing

- Hardness and Machinability

- Color Codes

- Handling and Shipping

- Storage

- Weight

- Metric vs Inch

- Applications

Nominal Sizes

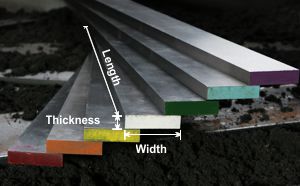

Ground Flat Stock is manufactured in various sizes of thicknesses, widths, and lengths. In North America the greatest variety of sizes are in fractional inches. Thicknesses range from 1/64″ to 2.5″ with many sizes in between. Widths range from 1/8″ to 14″. Lengths are 18″, 24″ 36″ or 72″. In metric GFS, the thicknesses range from 3mm to 10mm, the widths range from 15mm to 150mm, and the length is one meter.

Price vs. Performance

If you need to buy GFS on a tight budget, consider using W-1 steel. It isn’t ground like the other GFS pieces but the tolerances are similar because it is made in a well-controlled cold-drawing process. If you need greater variety of sizes, higher hardness, or more toughness, consider the O-1 GFS, which has the best cost/performance tradeoff. For even better hardness and toughness consider the other tool steels such as A-2, A-6, D-2, and M-2 in that order.

If your application requires extreme shock resistance, consider the S-7 GFS. If heat treating is not necessary for your application, consider the 4142 pre-hardened GFS or C1018 low-carbon GFS. For hardness, toughness, and corrosion resistance, consider the 410 420, or 440C stainless steel GFS.

Delivery Time and Inventory Quantity

The lead-time before shipment is and important aspect of ground flat stock. Many manufacturers carry large inventories of finished products. The flats are prepackaged and ready to ship on the same or next business day ordered. It is important do know whether any given size is actually in stock. Only a few websites have reliable information. Luckily DieSupplies.com indicates the lead time for each GFS size and whether it is on back-order.

Steel Grades, Sizes, and Manufacturers

There are at least four manufacturers of GFS in North American; Precision Marshall, DB&S Steel, Starrett, and Precision Brand. There are some common sizes that they all make. But there are remarkable, and sometimes confusing, differences. An easy way to visualize the difference is to read our Manufacturers Table which shows the steel grade, tolerance, and size of GFS pieces offered by the leading North American manufacturers.

Regular Tolerance vs Oversize Tolerance vs Cold-Drawn

GFS is manufactured in two different tolerance specifications, regular and oversize. There is also a specification for cold-drawn flat stock. To understand these differences read our page about Regular vs Oversize Tolerance.

Manufacturer Tolerances

Generally, all GFS manufacturers make their pieces to the same regular and oversize tolerances. But there are some subtle differences which may be important to your application. So please read our Manufacturer-Tolerance Table which shows the tolerances of GFS provided by the leading North American manufacturers.

Steel Grades and Processing

A variety of ground flat stock sizes and steel grades in North America are offered in popular steel grades. Please read our Steel Grades Table which shows available the steels and how each is processed.

Hardness and Machinability

The hardness and machinability of a piece of GFS depends on the steel grade. To understand the difference please read our Hardness and Machinability Table which shows the hardness and machinability of available steel grades.

Color Codes

Each ground flat stock manufacturer has its own color code for identifying steel grades. To understand the difference please read our Color Code Table.

Handling and Shipping

GFS should be handled and packaged with care to avoid damaging the carefully ground finish. A coating of light weight oil is recommended before shipping or storage to prevent corrosion. Manufacturers typically do an excellent job of packaging GFS for handling and shipment.

Storage

GFS should be kept clean and dry during storage. If stored on shelves, be sure not to exceed the shelf’s weight capacity. Temperature control is not required. The flats will need a coating of oil to prevent corrosion, especially If the storage environment has high humidity. Most manufacturers ship their flats coated with light-weight oil and individually packaged in a vapor-resistant envelope which has the size and steel grade clearly marked.

Weight

When Length, Width, and Thickness in inches are known, the weight of a piece of GFS can be estimated by the equation; Weight in pounds = Length x Width x Thickness x 0.283.

When Length, Width, and Thickness are given in millimeters, the weight of a piece of GFS can be estimated by the equation; Weight in Kg = (Length x Width x Thickness) / 127,658.

Metric vs Inch

Inch and metric GFS are similar products with some subtle and not so subtle differences. Inch GFS has a vast selection of steel grades, regular or oversize tolerances, and nominal fractional inch dimensions. Metric GFS choices are also available.

Applications

There are countless numbers of things that can be made with ground flat stock. For more information about using GFS please visit our Applications page.